Transfer express heat press has become a game-changer in the printing industry, offering businesses and enthusiasts alike an efficient and cost-effective solution for custom designs. Whether you're a small business owner or an entrepreneur looking to expand your offerings, understanding how this technology works is essential. This guide will provide you with everything you need to know about transfer express heat press, including its benefits, applications, and how to get started.

Custom printing has always been a lucrative market, but with the rise of on-demand services and personalized products, the demand for quick and reliable printing solutions has never been higher. Transfer express heat press technology addresses this need by allowing users to produce high-quality prints in a matter of minutes. This method not only saves time but also reduces costs associated with traditional printing methods.

In this comprehensive article, we will explore the intricacies of transfer express heat press, from its basic principles to advanced techniques. By the end of this guide, you will have a solid understanding of how this technology can transform your business and help you stay competitive in the ever-evolving printing industry.

Read also:Home Depot Port Charlotte Your Ultimate Guide To Home Improvement

Table of Contents

- What is Transfer Express Heat Press?

- How Does Transfer Express Heat Press Work?

- Benefits of Transfer Express Heat Press

- Applications of Transfer Express Heat Press

- Choosing the Right Heat Press Machine

- Materials and Supplies Needed

- Step-by-Step Guide to Using Transfer Express Heat Press

- Common Issues and Troubleshooting

- Cost Analysis and ROI

- Future Trends in Transfer Express Heat Press Technology

What is Transfer Express Heat Press?

Transfer express heat press refers to a printing method that uses heat and pressure to transfer custom designs onto various materials, such as fabric, ceramics, and metal. This process is widely used in the apparel industry for creating personalized t-shirts, hats, and other garments. Unlike traditional screen printing, which can be time-consuming and expensive, transfer express heat press allows for quick and cost-effective production of custom designs.

Key Features of Transfer Express Heat Press

- Rapid production capabilities

- Compatibility with a wide range of materials

- High-quality prints with vibrant colors

- Easy-to-use technology for beginners and professionals alike

According to a report by Grand View Research, the global heat press machine market size was valued at USD 3.5 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 5.4% from 2023 to 2030. This growth is driven by increasing demand for customized products and the expansion of e-commerce platforms.

How Does Transfer Express Heat Press Work?

The transfer express heat press process involves applying heat and pressure to transfer a pre-printed design onto a substrate. The design is typically printed on special transfer paper using an inkjet or laser printer. Once the design is ready, it is placed onto the material and pressed using a heat press machine, which applies the necessary heat and pressure to bond the design permanently.

Steps Involved in the Process

- Design creation: Use graphic design software to create your custom design.

- Printing: Print the design onto transfer paper using a compatible printer.

- Material preparation: Ensure the material is clean and free of any debris.

- Heat pressing: Place the printed design onto the material and apply heat and pressure using a heat press machine.

This method is particularly popular for its ability to produce full-color prints with fine details, making it ideal for complex designs and photographs.

Benefits of Transfer Express Heat Press

Transfer express heat press offers numerous advantages over traditional printing methods, making it a preferred choice for many businesses. Some of the key benefits include:

- Cost-effectiveness: Lower setup costs and minimal waste compared to screen printing.

- Speed: Faster production times, allowing for quicker turnaround on orders.

- Versatility: Compatible with a wide range of materials and substrates.

- High-quality results: Produces vibrant, long-lasting prints with excellent color reproduction.

A study published in the Journal of Textile Science & Engineering highlights the growing popularity of heat press technology in the textile industry, attributing its success to its ability to meet the demands of modern consumers for personalized and customizable products.

Read also:Julian Edelmans Weight And Height A Comprehensive Look At The Nfl Star

Applications of Transfer Express Heat Press

Transfer express heat press technology is widely used across various industries, thanks to its versatility and adaptability. Some of the most common applications include:

- Apparel printing: Custom t-shirts, hoodies, and hats.

- Home decor: Personalized mugs, tiles, and coasters.

- Marketing materials: Branded promotional items such as bags and pens.

- Art and crafts: Unique gifts and artistic creations.

With the increasing demand for personalized products, businesses that adopt transfer express heat press technology can tap into a lucrative market and offer a wider range of products to their customers.

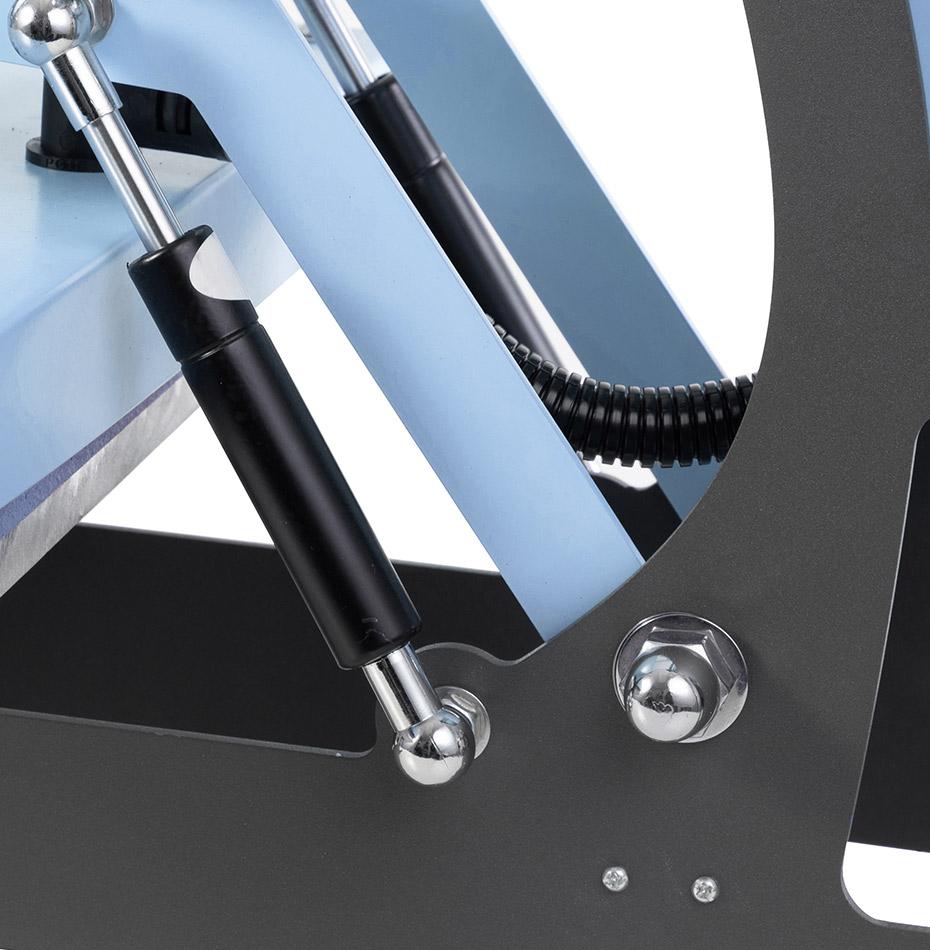

Choosing the Right Heat Press Machine

Selecting the right heat press machine is crucial for achieving optimal results. When choosing a machine, consider factors such as:

- Size and capacity: Ensure the machine can accommodate the materials you intend to print on.

- Temperature control: Look for machines with precise temperature controls to ensure consistent results.

- Durability: Invest in a machine built to last, especially if you plan to use it frequently.

- Additional features: Consider features such as digital displays, automatic shut-off, and adjustable pressure settings.

Popular brands like Cricut, Brother, and Epson offer a range of heat press machines catering to different needs and budgets. Reading reviews and comparing specifications can help you make an informed decision.

Materials and Supplies Needed

To get started with transfer express heat press, you will need the following materials and supplies:

- Heat press machine

- Transfer paper

- Inkjet or laser printer

- Substrate materials (e.g., fabric, ceramics, metal)

- Protective gloves and heat-resistant mats

Investing in high-quality materials and supplies is essential for achieving professional results. Always follow the manufacturer's guidelines for best results.

Step-by-Step Guide to Using Transfer Express Heat Press

Here is a step-by-step guide to using transfer express heat press:

- Create your design using graphic design software.

- Print the design onto transfer paper using a compatible printer.

- Prepare the material by cleaning it and ensuring it is free of any debris.

- Set the heat press machine to the recommended temperature and pressure settings.

- Place the printed design onto the material, ensuring proper alignment.

- Apply heat and pressure for the recommended time, usually 15-30 seconds.

- Allow the material to cool before peeling off the transfer paper.

Following these steps will help you achieve professional-quality prints every time.

Common Issues and Troubleshooting

While transfer express heat press is generally easy to use, some common issues may arise. Here are a few troubleshooting tips:

- Design not transferring properly: Check the temperature and pressure settings and ensure the material is compatible.

- Color fading: Use high-quality transfer paper and ensure the design is printed correctly.

- Bubbles or wrinkles: Ensure the material is flat and free of any debris before pressing.

Consulting the machine's manual or reaching out to the manufacturer's customer support can also help resolve any issues you may encounter.

Cost Analysis and ROI

Investing in transfer express heat press technology can lead to significant cost savings and increased revenue. While the initial investment may vary depending on the machine and materials, the long-term benefits often outweigh the costs. According to a report by Statista, the global custom apparel market was valued at USD 20 billion in 2022, with e-commerce driving much of the growth.

By offering custom printing services, businesses can tap into this growing market and increase their profitability. Calculating your return on investment (ROI) involves comparing the cost of equipment and materials to the revenue generated from custom orders.

Future Trends in Transfer Express Heat Press Technology

As technology continues to evolve, so does the field of transfer express heat press. Some future trends to watch for include:

- Advancements in ink and transfer paper technology for improved print quality.

- Integration with digital platforms for seamless order processing.

- Increased focus on sustainability and eco-friendly materials.

Staying informed about these trends can help businesses remain competitive and meet the changing demands of their customers.

Conclusion

Transfer express heat press technology offers a versatile and cost-effective solution for businesses looking to expand their custom printing offerings. By understanding the basics of this technology and following best practices, you can achieve professional-quality results and tap into a growing market. We encourage you to share your experiences and insights in the comments below and explore our other articles for more tips and tricks on growing your business.

Don't forget to subscribe to our newsletter for the latest updates and exclusive content. Together, let's revolutionize the printing industry!